PLCs via S7 Protocol

Mobile alerting with tracking & escalation for PLC's via S7 protocol

![]() Why Enterprise Alert

Why Enterprise Alert

When a machine has a problem or needs maintenance it is often just indicated by an indicator lamp or by a small display attached to the machine. However, during daily operations, the plant manager cannot check each machine all the time. For a smooth and uninterrupted production process, it is essential to know when a machine is in a critical status or needs maintenance.

Take your PLC display with you. Pairing PLC’s with Enterprise Alert can enhance your daily operations by informing maintenance teams, production managers, or engineers on the shop floor or in the field about critical machine states no matter where they are.

![]() How it Works

How it Works

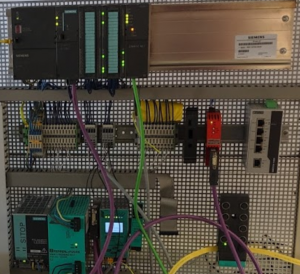

A Programmable Logic Controller (PLC) is an industrial, often ruggedized, device for controlling manufacturing processes, such as machines, assembly lines, or robots. PLC’s can have various digital and analog inputs and outputs for connecting sensors and actors. They can thus be used for consolidating data from temperature, humidity or vibration sensors, light barriers, or from I/O contacts.

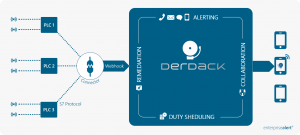

All it takes to pair PLC’s and Enterprise Alert is a connector app that accesses and processed the PLC data using the S7 protocol and from there sends REST requests to Enterprise Alert and thus an alert the responsible team.

![]() Integration Capabilities

Integration Capabilities

- Service engineers alerted via mobile push, text and voice

- Integration with Enterprise Alert via webhook

- Staff can acknowledge and take ownership for critical events that occur

- Alerts are escalated in case of no response

- Tracking and visibility of problem solutions

- Integrated on-call duty planning

Alert on critical IoT device states

![]() Scenarios

Scenarios

- Maintenance management / quality assurance

- Direct machine to person communication

- Industrial IoT

- Industry 4.0

- IoT service alerting

- IoT device management

- IT, manufacturing, utility, oil and gas, agriculture, etc.

How to Integrate

In our example, we use a PLC with a couple of I/O contacts connected. We retrieve the I/O information from the PLC and send an alert to our Enterprise Alert team in case an I/O contact is closed.

Prerequisites

A preexisting Enterprise Alert installation with Users, Teams, and a preconfigured REST endpoint

A PLC (supporting the S7 protocol)

Integration Steps

- Connect the PLC

If not already done we set up the PLC. That means we connect it to the network and connect the sensors or I/O contacts. The PLC needs to be reachable via IP and we need to know the address data within the PLC.

- The Connector App

The connector app runs on a dedicated machine (Windows or Linux) and is based on Node.js. It connects to the PLC via the S7 protocol and sends event information to Enterprise Alert when certain conditions are met.

In order to query information from the PLC’s some additional information is required. This is for example information about the IP addresses of the PLCs, the data addresses within the PLC’s and the conditions when to trigger events.

This information is contained in the database table “S7ConnectorAlerts”. Here comes a simplified description of the contained columns.IP Primary Key IP IP address of the PLC Rack S7 rack identifier Slot S7 slot identifier Message An additional message parameter for the event Location An additional location parameter for the event Priority Alert priority AlertAddress The address within the PLC to be queried AlertOn Value that the PLC address must get to fire the event Besides this, the Enterprise Alert webhook URL including the API Key needs to be configured in the connector app. The app will query the PLCs in certain intervals and send events to Enterprise Alert when a condition is met, in our case when an I/O contact is closed.

Please contact us for more information about how to obtain the connector app.

- Network Considerations

For the test setup, the PLC just needs to be reachable from our connector app (see above). In production, the PLC might be in a closed process network with no access to the Internet. In this case, the connector app can be installed in another network, for example in the office network or in the DMZ. From there it requests data from the PLCs using dedicated IP addresses and ports and on the other side, it communicates with the Enterprise Alert installation via HTTPS.

- Test It

This is it. You can now test your IoT scenario by simulating an appropriate event, in our case you can close an I/O contact. You will then receive alerts from Enterprise Alert.

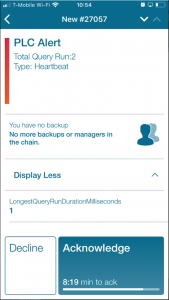

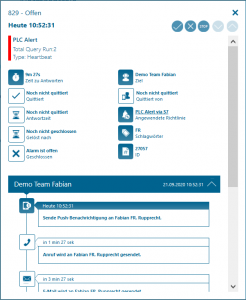

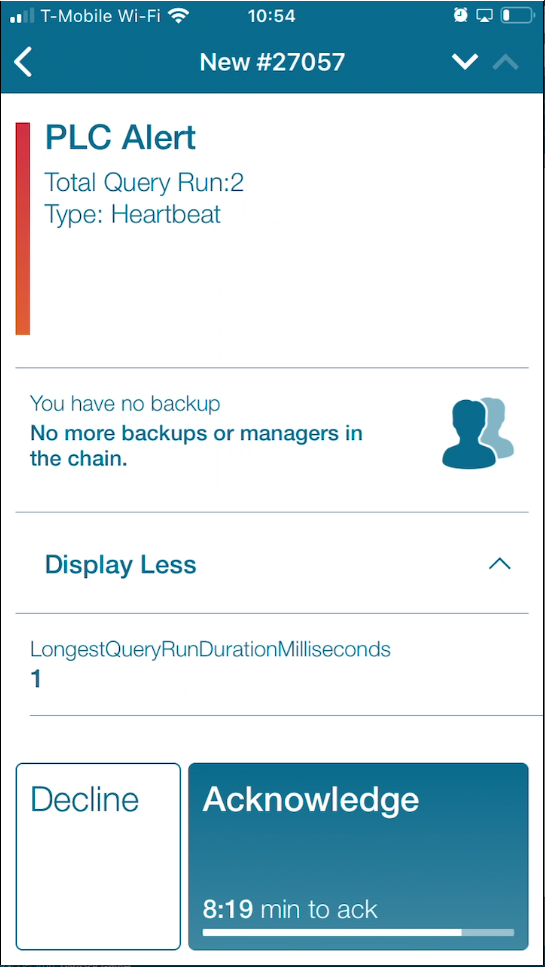

Notifications within the Enterprise Alert mobile app

Enterprise Alert comes complete with a mobile app allowing for all critical alert details to be seen from anywhere. Users can acknowledge and take ownership of alerts and with remote actions, even resolve them. Team members collaborate with their peers so that even if an on-call person is not the SME, that person is easily within reach via voice call, text or email.

A centralized Alert Center can be viewed from the web portal. All alerts, whether active, overdue or closed are visible to EA admins. Ownership and even delegation is as easy as drag-and-dropping the alert to the person/team.