Real-time mobile alerting for better shopfloor maintenance

Maintenance of machines is an incredibly important task. And it is important to fix a machine before it completely fails. In reactive maintenance scenarios, speed of response is key. Once an issue is detected is important to communicate as reliably and quickly as possible to the right engineer. Ideally, the machine is connected directly to team of mobile engineers in charge and can let them know what exactly happened and what needs to be fixed. Putting any relevant PLC alarm on your engineer’s mobile devices is the way.

Link your PLCs to your engineers

Most machinery is nowadays controlled and managed by a PLC – Programmable Logic Controller. Industrial networks connect PLCs to MES (Manufacturing Execution Systems) or SCADA systems (Supervisory Control And Data Acquisition), for instance using the S7 protocol.

As Derdack Enterprise Alert, our high-performance alerting and incident response software, “understands” the S7 protocol, it can fetch any data including alarms from PLCs and can thus link your maintenance teams with all machinery on your shopfloor in real-time. Any relevant PLC alarm can be retrieved, filtered, and configured to lead to a real-time alert notification process. Such alerting process is managed in a fully automated manner by Enterprise Alert and includes the identification of the responsible team, the check of the team members on duty, the selection of proper communication channels, alert delivery and confirmation tracking and any escalation procedure in case of no response.

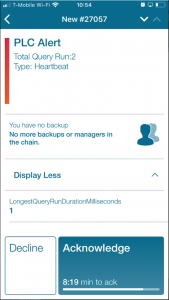

PLC alarm on mobile devices

Derdack Enterprise Alert also comes with a convenient, native mobile app. A mobile app is a powerful tool and superior to common alert methods like SMS text. In this app, maintenance engineers see in real-time who responded and who took over which alert or maintenance job. It takes one click to acknowledge an alert. This provides a sense of ownership which is not possible (or cumbersome) with SMS text alerts. No further communication to search for idle team members or to confirm job ownership is necessary. Later shifts can easily see what happened in the previous shifts, and which jobs were completed. One-touch communication options helps engineers to contact each other to solve problems jointly.

Derdack Enterprise Alert also comes with a convenient, native mobile app. A mobile app is a powerful tool and superior to common alert methods like SMS text. In this app, maintenance engineers see in real-time who responded and who took over which alert or maintenance job. It takes one click to acknowledge an alert. This provides a sense of ownership which is not possible (or cumbersome) with SMS text alerts. No further communication to search for idle team members or to confirm job ownership is necessary. Later shifts can easily see what happened in the previous shifts, and which jobs were completed. One-touch communication options helps engineers to contact each other to solve problems jointly.

Enterprise Alert provides:

- Automated real-time notifications to maintenance teams

- Notifications to active personnel on duty only

- Simplified shift punch-in and out

- Integrated duty scheduling for automated shift hand-over

- 1-click job assignment confirmations

- Real-time transparency on job ownership and resolution progress

A central piece is the secure mobile app which is available for iOS and Android which is used for alert/job management, incident-related communication and resolution management.

S7 protocol for PLC connectivity

Derdack Enterprise connects directly to your PLCs using the S7 protocol and can query thousands of PLCs. Alternatively, you can integrate your MES or SCADA system. Read more about our S7 protocol integration here.

Benefits

Automated mobile maintenance alerts lead to a much faster response to any disturbance or even interruption of manufacturing or machinery operations. It significantly reduces the mean-time-to-response. Maintenance alerts are targeted to right personnel who is actively on duty.

Small, medium and large companies alike are looking for the best approach to embrace the “Industrie 4.0” initiative. Clearly, value comes first and operational excellence is one target. Experts agree on a step-by-step approach. Because Enterprise Alert seamlessly and effortlessly integrates with existing infrastructure, it is a low-barrier entrance to better operations and a building block of the smart and automated factory. The return-on-investment is quick through the simplification and automation of formerly manual processes.